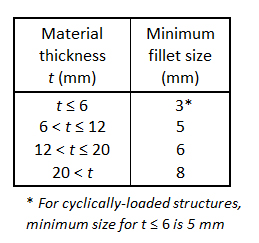

The minimum size of a fillet weld as measured should comply with Table 4.4 of CSA W59-13, unless a larger size is required to provide the calculated weld resistance. The long-standing code provision for minimum fillet size aims to reduce the cooling rate. The presence of hydrogen and fast cooling are major contributing factors for cold cracking. In W59-13, the minimum size requirement has been relaxed where low hydrogen consumables are used.

The essence of Table 4.4 is shown in the table below. For consumables with a hydrogen content in conformance with the H8 requirement or lower, t is taken to be the thickness of the thinner part joined. Otherwise, t equals the thickness of the thicker part joined; however, the weld size need not exceed the thickness of the thinner part provided particular care is taken to provide sufficient heat input to ensure weld soundness. The requirement of Table 4.4 need not apply when:

- welding attachments to members not subjected to calculated load effects, or

- welding procedures have been established to prevent cracking in accordance with W59-13.

W59-13 also specifies preheat requirements as applicable.