In consideration of ultimate limit states of composite beams in service alone, full composite design generally results in the lightest beam sections. Partial composite capacity, however, usually suffices because factors other than the ultimate limit states of the composite beam often dictate the steel beam size and the percentage of composite shear connection. These factors are:

- In order to benefit from one of the advantages of steel construction, beams are unshored. In that case, construction loading conditions may govern;

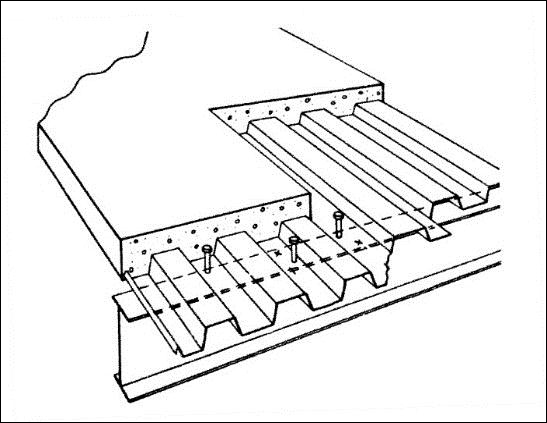

- Since the deck flutes typically run perpendicular to the beam, as shown in Figure 1, (and wide-rib profile deck should be used for optimal stud shear capacity) full composite design often results in placing multiple studs per flute resulting in inefficient use of shear studs due to overlap of concrete shear cones; and

- Live load deflection or floor vibration control may govern the design.

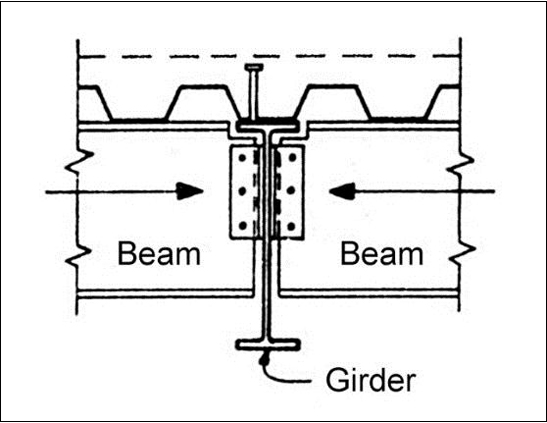

In accordance with S16-14, 40% or larger composite shear connection must be provided for composite resistance. Due to the above-mentioned factors, most composite beams are designed for 40% to 60% shear connection. However, composite girders are usually connected for higher composite capacity because the deck flutes run parallel to the girder and, during construction, the girder is often laterally braced by the beams framing into it (Figure 2). Where composite action is only required for stiffness measures, S16 permits 25% shear connection as the minimum.

Figure 1: Deck Perpendicular to Beam |  Figure 2: Deck Parallel to Girder |

|---|