Advantages of HSS as braces

The popularity of hollow structural section bracing stems from two facts:

a) Square and circular HSS do not have a minor axis

Typically, the compressive resistance, Cr, for a brace is considerably smaller than its tensile resistance, Tr (for CSA G40.21 350W steel, Cr for a brace at the maximum permissible slenderness limit, KL/r = 200, is about 0.13Tr ). Hence, its compressive resistance usually governs the design while its tensile capacity dictates the connection design forces and other elements in Moderately Ductile and many Limited-Ductility Concentrically Braced Frames. Because the cross sections of square and circular HSS braces do not have a minor axis this disparity is minimized.

b) Cross section compactness

In order to preclude local buckling, brace members are required to meet stringent b-to-t limits. HSS, as closed sections, enjoy a clear advantage.

These advantages usually outweigh any inherent drawbacks, such as more challenging connection design and detailing.

Increase in probable strength

While the specified minimum yield strengths for common grades of hollow structural sections remain unchanged, the minimum value for their probable yield stress, RyFy, as specified in Clause 27.1.7 of CSA S16, has been increased from 385 MPa to 460 MPa. This higher value was introduced in S16-09 to reflect the strength characteristics of CSA G40.21 350W and ASTM A500 Grade C products.

With the exception of Conventional Construction, the yielding capacities of dissipating elements control the design forces in other parts of the seismic-force resisting system (SFRS). For Concentrically Braced Frames, CBF, the probable tensile and compressive capacities of braces are calculated using their probable yield stress, RyFy. Since the probable capacities of braces usually dictate the design forces for columns, beams, roof and floor diaphragms, foundation and connections, this increase generally affects the design and construction of the entire SFRS.

What are the alternatives?

The designer may also consider:

a) SFRS other than Moderately Ductile and Limited Ductility CBF; and

b) The viability of other shapes as braces.

Other SFRS

Many factors affect the selection of SFRS, including seismicity, building Importance Category, Site Class, mass and height of buildings, etc. Other SFRS are considered in these examples:

- For areas of low seismicity, Conventional Construction, CC, (including braced frames) is usually considered (exception: CC is not permitted for Post-disaster buildings);

- For areas of high seismicity, Eccentrically Braced Frame, EBF, should be considered;

- Beam hinging (instead of brace yielding) is permitted for Low-rise (height ≤ 20 metres) Limited-Ductility Chevron CBF in areas of moderate seismicity; and

- For taller buildings in areas of moderate seismicity, EBF may also be considered.

Other shapes as braces

Shapes other than HSS may be viable alternatives when favourable conditions present themselves, for example:

- Where the brace forces are large, e.g., a large/heavy multi-storey frame, may try W-sections;

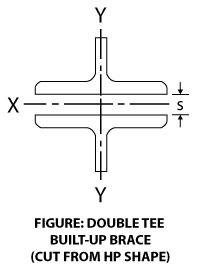

- For one- and two-storey tension-only Limited-Ductility frames, may also try double angles, double channels and double tees (as shown in the figure); and

- Where Class 2 sections are permitted for low-rise Limited-Ductility Chevron frames, may also try double tees, etc.

It should be noted that the design and construction of the above-mentioned built-up brace members must also comply with the requirements of clause 27.5.3.3 of S16-14.

In the end, HSS will most likely remain the popular choice in most applications.